How to give customers a better understanding of PVD or CVD coating in the application of choice?

Views : 423

Update time : 2017-10-23 16:45:04

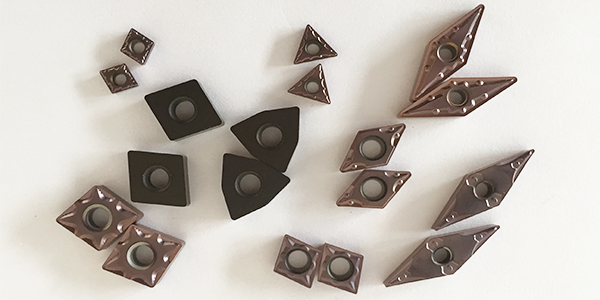

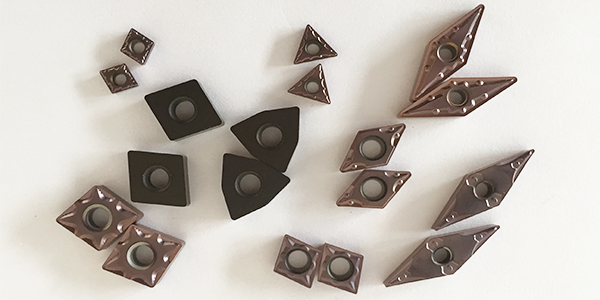

PVD (physical vapor deposition) and CVD (chemical vapor deposition) are two different principles of coating method. PVD coating and CVD coating also has its own different characteristics and application areas. CVD coating deposition temperature is higher, up to 1000 degrees Celsius. The high deposition temperature will have some effect on the tool base material. At present can only be applied to the part of the cutting blade coating. In addition, CVD coating process will produce chemical waste, so not environmentally friendly. The advantage of the CVD coating is that a thick coating (thickness up to 20 μm or more) can be deposited with good adhesion and deposition of the Al2O3 coating material. PVD coating deposition temperature is low (about 500 degrees Celsius), environmental protection, but the coating thickness is relatively thin, can not be deposited α-phase alumina, CVD coating is generally applied to the cutting blade cutting, especially roughing. The PVD coating can be applied to the overall tool and cutting blade milling, drilling, hobbing, fine and semi-fine processing. In particular, EJ Carbide's second-generation ultra-nitrogen coating using sputtering technology overcomes the presence of coating stress, can deposit coatings with a thickness of 12 μm, and ensures a very good adhesion to the coating. This thick PVD coating is ideal for roughing and finishing of cutting inserts. And these applications have previously been the traditional application areas of CVD coating. But for some applications, such as roughing, CVD coating is still irreplaceable.