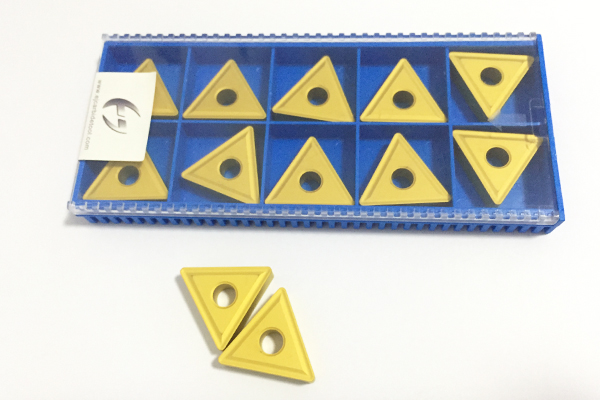

CNC carbide insert material

Views : 413

Update time : 2018-09-18 15:09:19

CNC carbide insert material

Coated insert blade

1) CVD vapor deposition coating The coating material is TiC, which improves the durability of cemented carbide tools by 1-3 times. Thick coating; blunt edge; help to improve speed life.

2) PVD physical vapor deposition coating The coating materials are TiN, TiAlN and Ti(C,N), which improves the durability of cemented carbide tools by 2-10 times. The coating is thin; the cutting edge is sharp; it helps to reduce the cutting force.

★The maximum thickness of the coating is ≤16um

CBN and PCD

Cubic Boron Nitride (CBN) Cubic Boron Nitride is second only to diamond in hardness and thermal conductivity. It has high thermal stability and good chemical stability, so it is suitable for processing hardened steel, hard cast iron, superalloy and hard alloy. .

Polycrystalline Gold Body (PCD) When used as a cutting tool, polycrystalline diamond body is sintered on a cemented carbide substrate and can be used for non-metallic and non-ferrous alloy materials such as hard alloys, ceramics, and high-silicon aluminum alloys. Finishing.

★ISO machine clip insert blade material classification method ★

Steel: P05 P25 P40

Stainless steel: M05 M25 M40

Cast iron: K05 K25 K30

★ The smaller the number, the harder the blade, the better the wear resistance of the tool and the poor impact resistance.

★ The larger the number, the softer the blade, the better the impact resistance of the tool and the poor wear resistance.

Coated insert blade

1) CVD vapor deposition coating The coating material is TiC, which improves the durability of cemented carbide tools by 1-3 times. Thick coating; blunt edge; help to improve speed life.

2) PVD physical vapor deposition coating The coating materials are TiN, TiAlN and Ti(C,N), which improves the durability of cemented carbide tools by 2-10 times. The coating is thin; the cutting edge is sharp; it helps to reduce the cutting force.

★The maximum thickness of the coating is ≤16um

CBN and PCD

Cubic Boron Nitride (CBN) Cubic Boron Nitride is second only to diamond in hardness and thermal conductivity. It has high thermal stability and good chemical stability, so it is suitable for processing hardened steel, hard cast iron, superalloy and hard alloy. .

Polycrystalline Gold Body (PCD) When used as a cutting tool, polycrystalline diamond body is sintered on a cemented carbide substrate and can be used for non-metallic and non-ferrous alloy materials such as hard alloys, ceramics, and high-silicon aluminum alloys. Finishing.

★ISO machine clip insert blade material classification method ★

Steel: P05 P25 P40

Stainless steel: M05 M25 M40

Cast iron: K05 K25 K30

★ The smaller the number, the harder the blade, the better the wear resistance of the tool and the poor impact resistance.

★ The larger the number, the softer the blade, the better the impact resistance of the tool and the poor wear resistance.