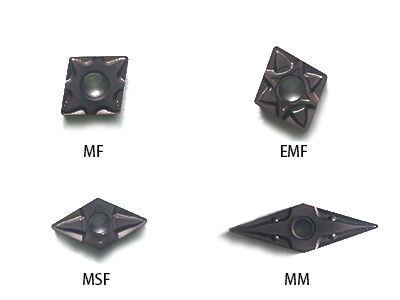

Stainless Steel Processing Chipbreaker

1.EMF-Unique groove design ensuring the sharp edge, also increase the edge strength, an effective solution to chip breaking, cutting temperature, sticky knife, hardening and other processing difficulties during stainless steel processing, can get higher processing effectiveness than-MSF.

2.MSF-Double rake angle three-dimensional groove design,sharp cutting edge, low cutting force, effective solution to stainless steel processing chip breaking, high cutting temperature, sticky knife, hardening and other processing difficulties, blade angle design with a good control of the chip flow,get high quality processed surface.

3.MF-For the stainless steel with large plasticity, strong adhesive,design a special rake angle and blade angle of the groove,the blade edge sharp, small cutting resistance,and can well control the cutting flow,access to high-quality surface for stainless steel finishing.

4.MM-Unique groove design in ensuring the edge of the sharp, based on the increase in the impact resistance of the blade, can effectively prevent the chip chip accumulation, suitable for semi-finishing stainless steel materials.