Micro-hole Processing Technology of Circuit Board Composite(1)

Views : 457

Update time : 2017-07-07 17:50:00

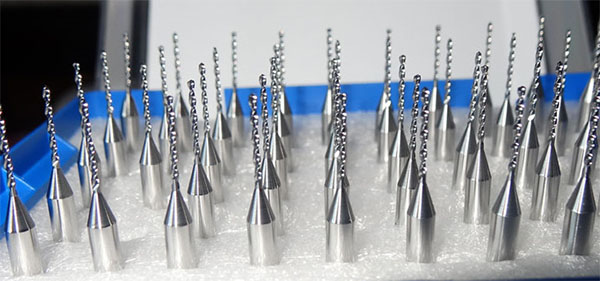

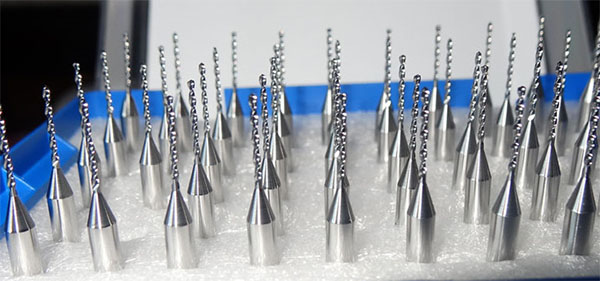

With the rapid development of electronic technology, modern electronic products become smaller and smaller, more and more complex functions, the electronic components from the support and interconnection of the printed circuit board (PCB) from single-sided development to double-sided, more Layer, to the high precision, high density and high reliability direction, the volume is shrinking, the density exponentially increased, requiring the processing of the circuit board aperture is getting smaller and smaller, the number of holes more and more, the distance between the more and more small. Therefore, the need for high-quality micro-hole processing technology and high performance printed circuit board drill bit.

Printed circuit board specifications are more complex,various types of products. Here describes the printed circuit board in the most widely used epoxy resin composite material of small holes (diameter 0.6mm below the hole, 0.3mm below the microporous) processing technology. Composite material circuit board brittle, high hardness, high fiber strength, toughness, low interlayer shear strength, anisotropy, poor thermal conductivity and fiber and resin thermal expansion coefficient vary widely, when the cutting temperature is high, easy to The fiber around the cutting zone and the substrate interface to produce thermal stress; when the temperature is too high, the resin melt adhesion on the cutting edge, resulting in processing and chip removal difficulties. Drilling composite material cutting force is very uneven, easy to produce stratification, burr and splitting and other defects, processing quality is difficult to guarantee. This material is very abrasive to the tool, the tool wear is quite serious, the tool wear in turn will lead to greater cutting force and heat, if the heat can not be dispersed in time, will lead to PCB material in the low melting point components And the peeling between the composite layer and the layer. PCB composite materials are difficult to process non-metallic composite materials, the processing mechanism and metal materials are completely different. At present, micro-hole processing methods are mainly mechanical drilling and laser drilling.

Printed circuit board specifications are more complex,various types of products. Here describes the printed circuit board in the most widely used epoxy resin composite material of small holes (diameter 0.6mm below the hole, 0.3mm below the microporous) processing technology. Composite material circuit board brittle, high hardness, high fiber strength, toughness, low interlayer shear strength, anisotropy, poor thermal conductivity and fiber and resin thermal expansion coefficient vary widely, when the cutting temperature is high, easy to The fiber around the cutting zone and the substrate interface to produce thermal stress; when the temperature is too high, the resin melt adhesion on the cutting edge, resulting in processing and chip removal difficulties. Drilling composite material cutting force is very uneven, easy to produce stratification, burr and splitting and other defects, processing quality is difficult to guarantee. This material is very abrasive to the tool, the tool wear is quite serious, the tool wear in turn will lead to greater cutting force and heat, if the heat can not be dispersed in time, will lead to PCB material in the low melting point components And the peeling between the composite layer and the layer. PCB composite materials are difficult to process non-metallic composite materials, the processing mechanism and metal materials are completely different. At present, micro-hole processing methods are mainly mechanical drilling and laser drilling.